Introduction:

Molding is a certain process that may mildew the tough and specific materials through production of distinct commodities, spare components and different products. Vinyl commodity fabricating business is worldwide famous for its a wide scope of merchandise. Many vinyl upholstery manufacturers use Rotational Molding treatment to mold the stained plastic in to different styles, angles and layouts extremely comfortably with whole neatness. This rotational technology is widely utilised in manufacturing plastic solutions and lots of warhead covers.

Why Can This Molding Procedure Turning into Compulsory?

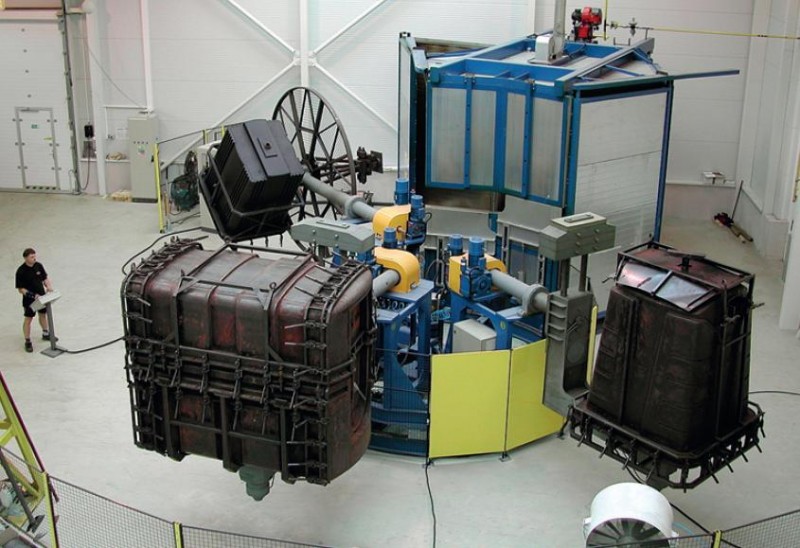

Molding technological innovation is too used in various manufacturing businesses and businesses across the globe. Basically, Rotomoulding can be a key process to mould different varieties of substances in some last designs and contours together with 100% required precision. Molding machine generally have a big, warmed hollow that's packed up with melted material like boiling plastic or alternative metals and materials. Quite a few manufacturers utilize this mandatory procedure to prepare distinctive kinds of those goods.

Is It This Molding Technologies Vital to Produce Plastic Products?

Rotational and straight molding procedures are getting to be very useful and effective for several types of manufacturing industries. The businesses manufacturing spare parts, warhead addresses, thin alloy covers, plastic and parts furniture are using this engineering. Plastics Rotational Molding technique supports most of producing firms that need to mildew a enormous number of their material very fast into desired designs and contours of unique products.

Multiple Features, Features and Functions of The Molding:

Today, there are many small and big sized molding devices and the systems that are hugely utilised in all kinds of industries. Actually; Rotational Molding technological innovation includes tons of specs, capabilities, functions as well as a number of industrial uses for various manufacturers.

Conclusion:

It is becoming famous amongst various industries touse the ideal quality and most innovative metering and straight casting machines. Manufacturers need to get and utilize Rotomoulding process to improve the contours, of specific spare components of various substances.

No comments:

Post a Comment