Hit brake tooling is one of the most essential aspects

in accomplishing correct and exact bends in sheet metal manufacturing.

It’s not merely about having the proper device, but also about working

with it correctly to obtain ideal outcomes. Learning the art of press

brake tooling is a crucial a part of metal fabrication. In this blog

post, we are going to go over essential techniques and strategies for

perfecting

press brake tooling.

Picking the right Tooling:

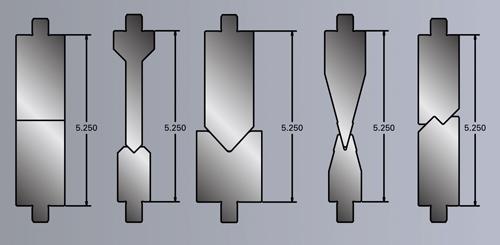

Selecting the right press brake tooling is essential for reaching ideal results in page metallic fabrication. A variety of press brake tooling is available for sale, with various styles and sizes. The choice of the best tooling is determined by the size of your substance, flex angle, and type of bend you need. Typically of thumb, select a resource using a minimum V-expire starting of eight instances the information density and ensure appropriate alignment of your punch and perish.

Accurately Creating Tooling:

Accurate and accurate setup of press brake tooling is actually a critical step in aluminum fabrication. A slight misalignment might cause the information to style or flex inaccurately, resulting in substandard quality. Set up tooling in line with the manufacturer’s instructions and be sure that the punch and expire are correctly in-line. Moreover, make certain that the V-perish is neat and free from trash and also the sheet metallic is concentrated on the die.

Suitable Lubrication:

Lubrication is an essential factor in press brake tooling. The usage of suitable lubrication brings about cleaner slashes, decreases rubbing, and prolongs the lifespan of punches and passes away. Implement lubrication in the impact and expire before each use and be sure that the page steel will not get any essential oil or oil through the tool.

Utilizing Correct Tonnage:

Utilizing the right tonnage is critical for the appropriate performing of press brake tooling. The quantity of push required for twisting the sheet aluminum is determined based on the thickness of your substance along with the preferred flex angle. Applying too much tonnage can damage the tooling that will create unneeded wear. Working at reduce tonnage could lead to very poor-top quality bends.

Normal Routine maintenance:

Typical upkeep of press brake tooling is vital for the optimum functioning. Clear the tooling after each use, remove all debris and check out for just about any damage. A ruined impact or die may result in suboptimal results and need more significant try to resolve.

Bottom line:

Perfecting the skill of press brake tooling is not any small accomplishment. Accomplishing exact and accurate bends in page metallic production needs consideration and rendering. The above-reviewed tips and techniques are a starting point for learning press brake tooling, and several other variables play a role in attaining desired final results. Regular exercise, ongoing understanding, and asking experts for guidance can help excellent press brake tooling and

No comments:

Post a Comment